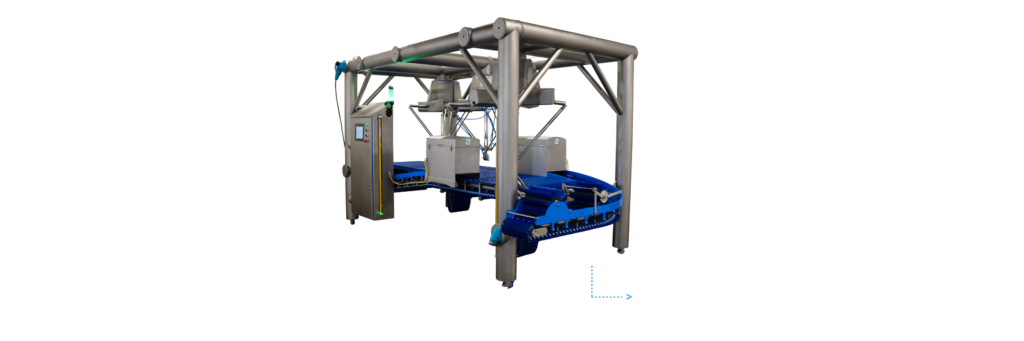

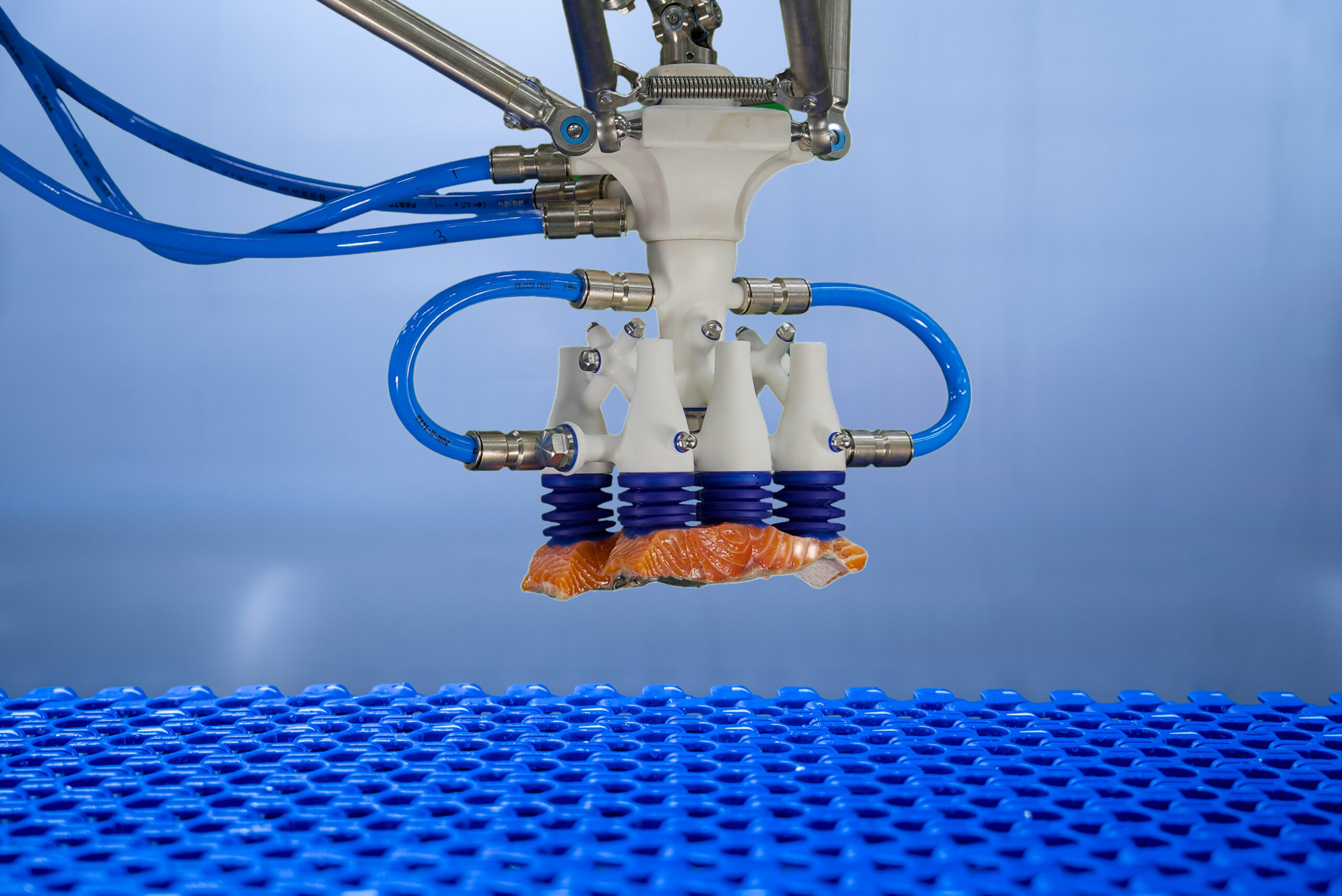

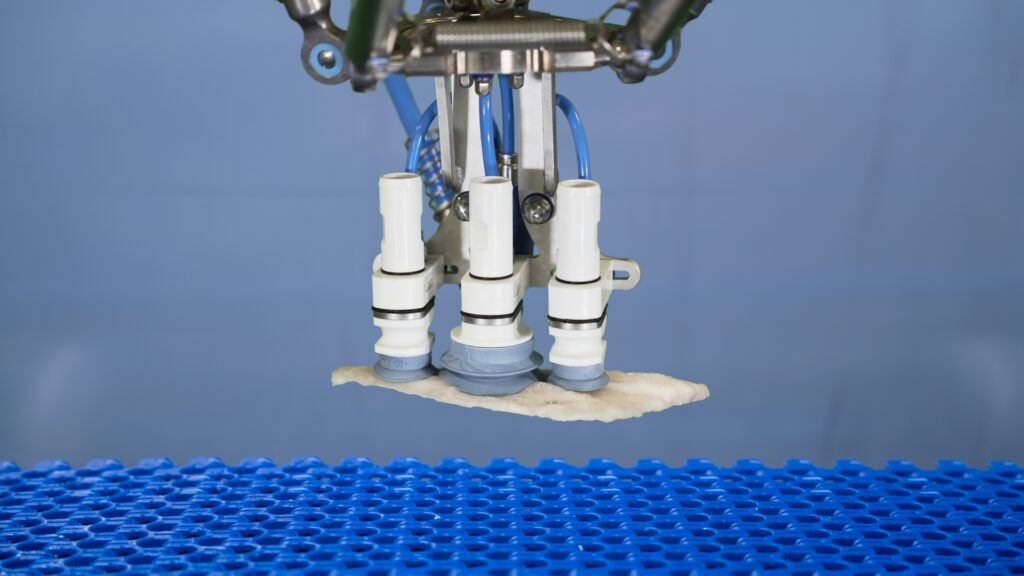

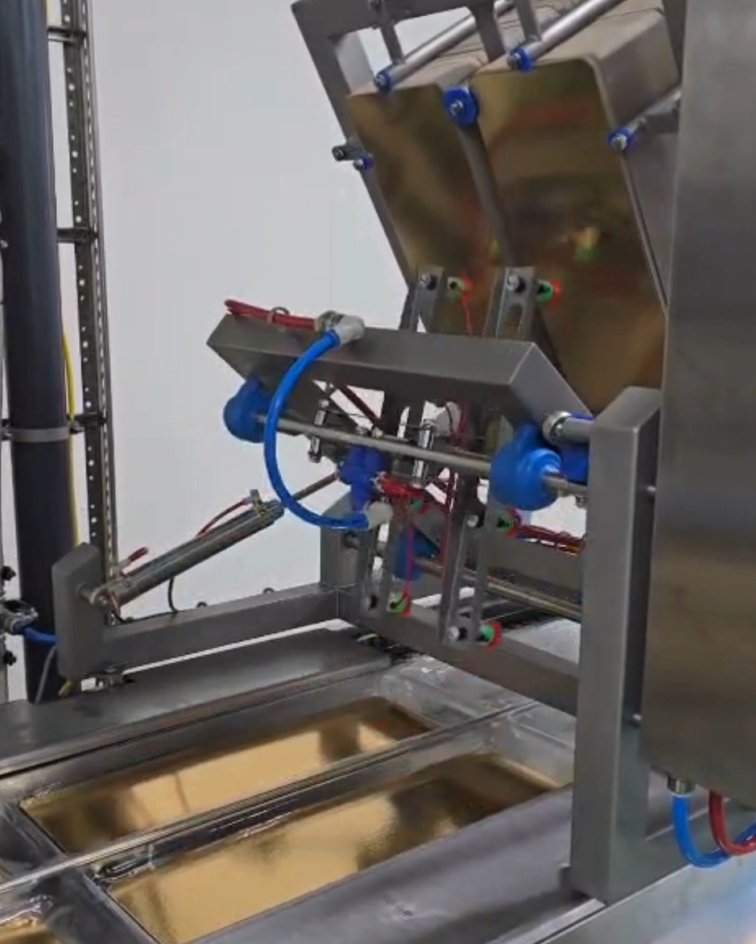

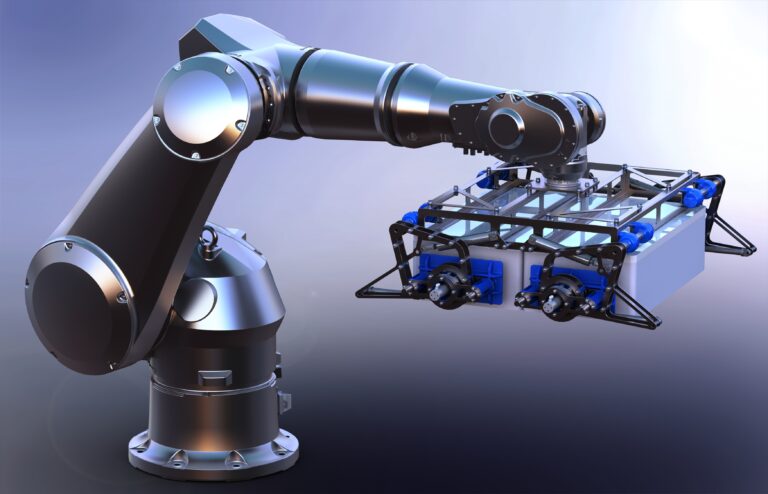

Reduce manual work

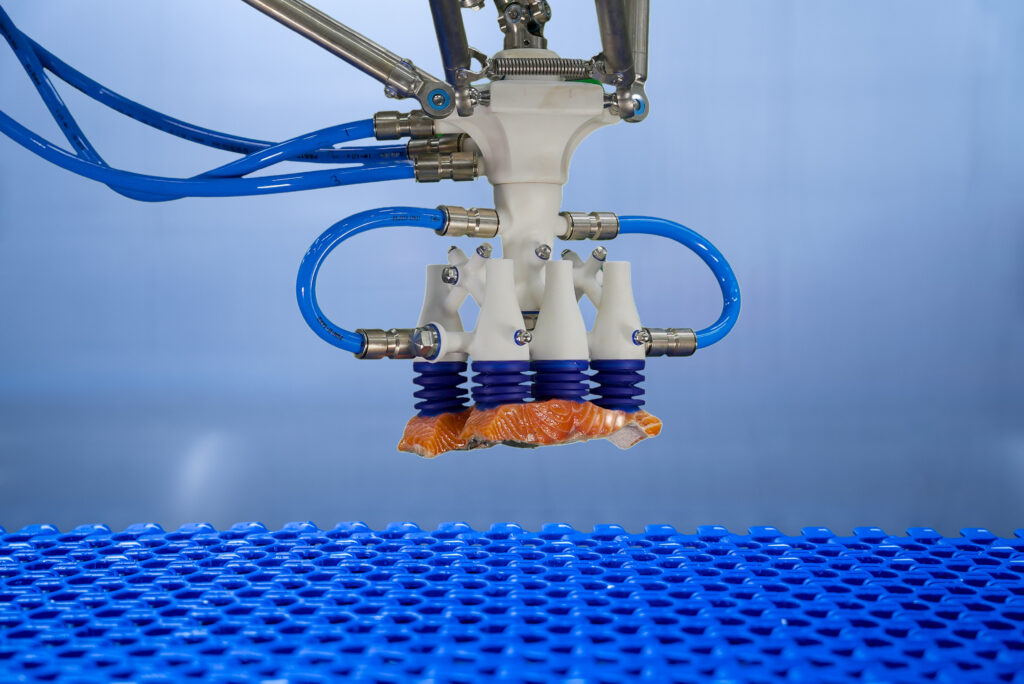

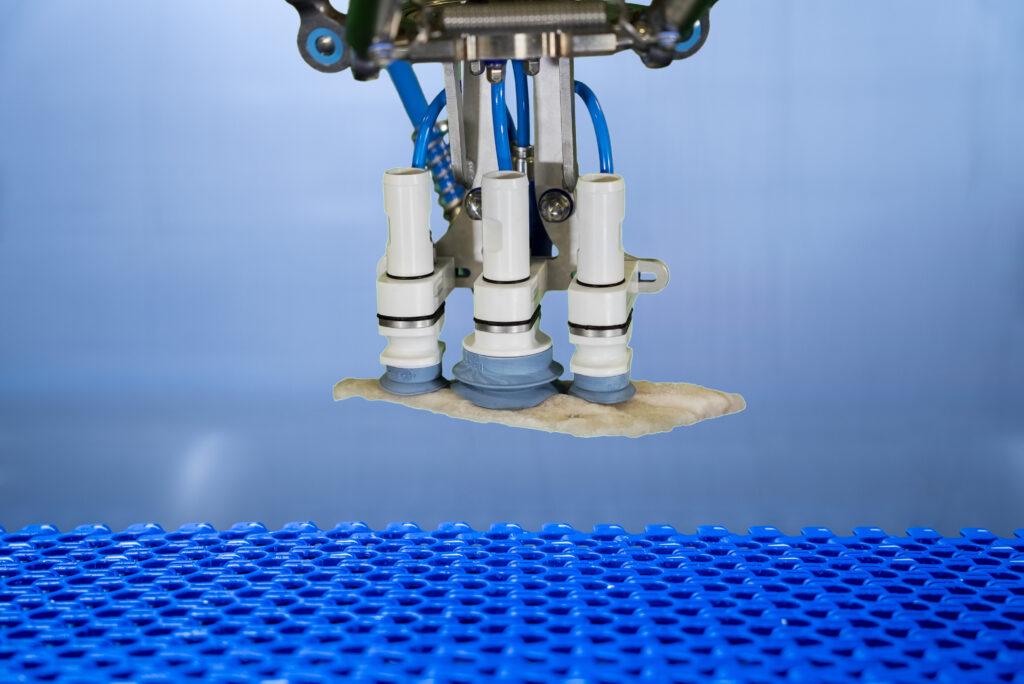

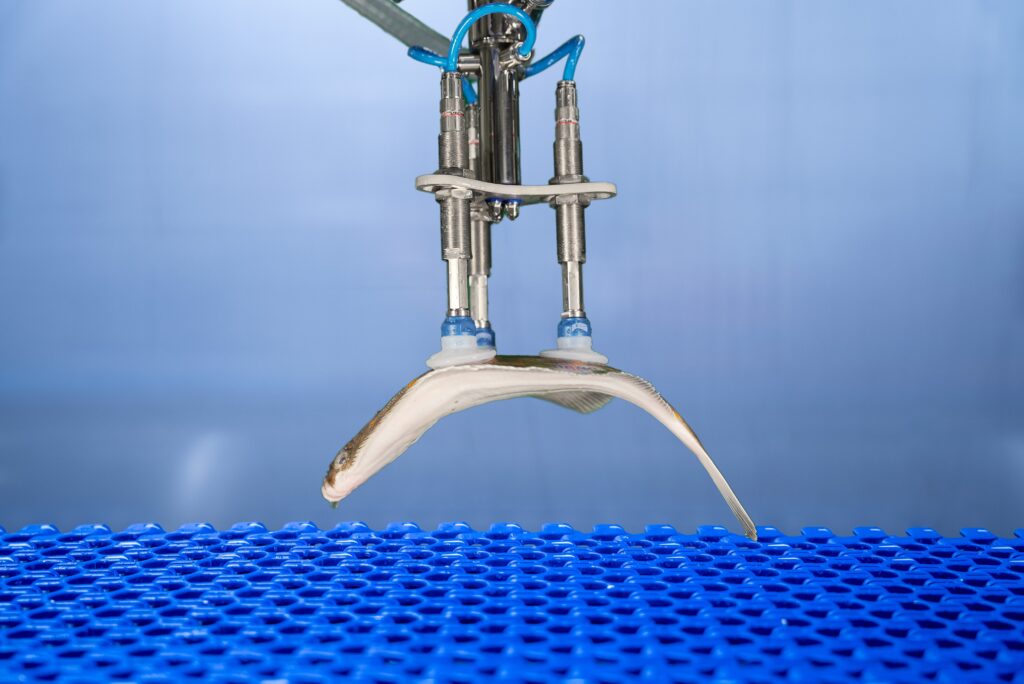

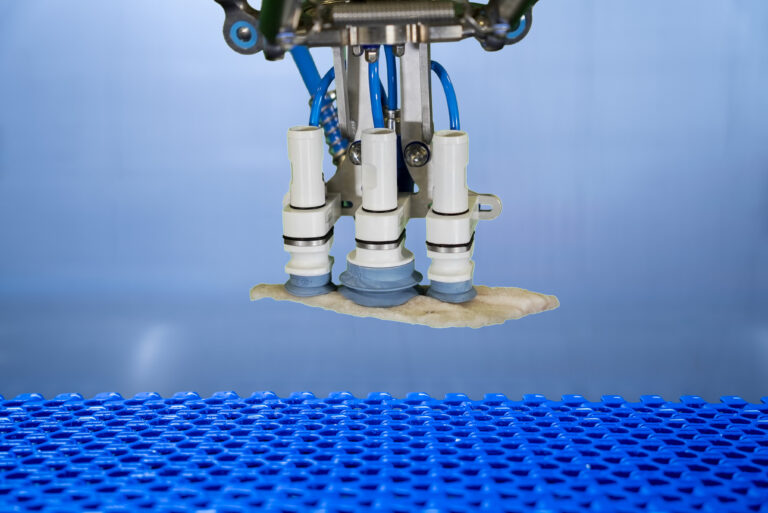

Our pick-and-place solution guarantees a higher production speed, reduces manual work and optimizes the production process. This allows you not only to meet your customers’ demands, but also to reduce your operational costs. When searching for foodmachinery solutions, choose our advanced pick-and-place technology and experience the perfect combination of hygiene, precision and efficiency in your production process.

Featured