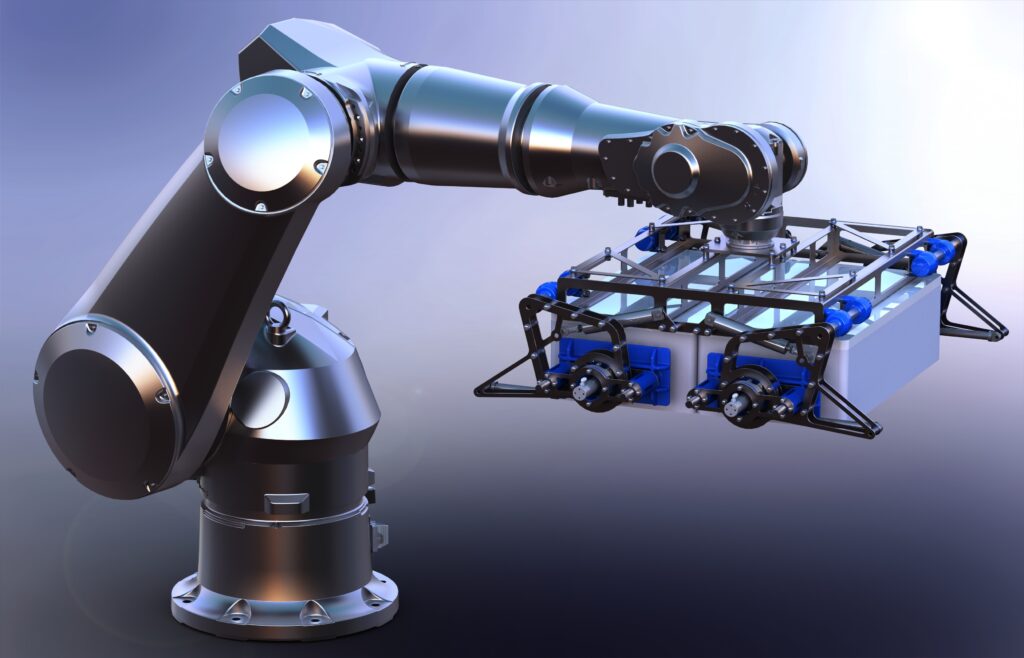

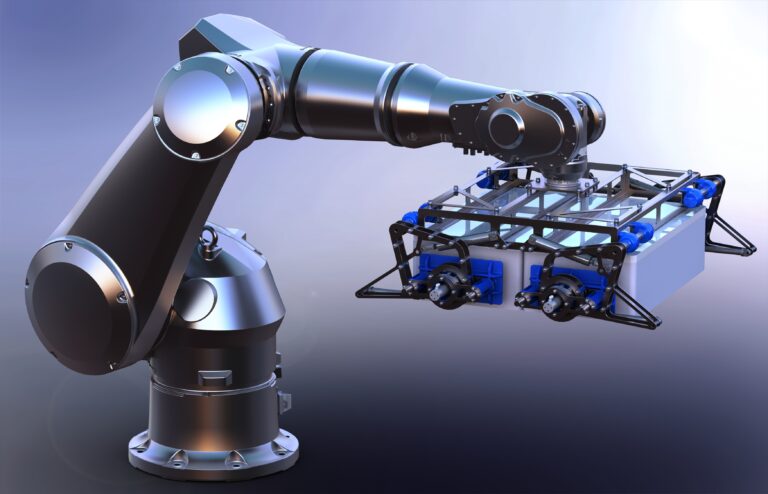

(De)palletizer

Our hygienic (de)palletizing solution

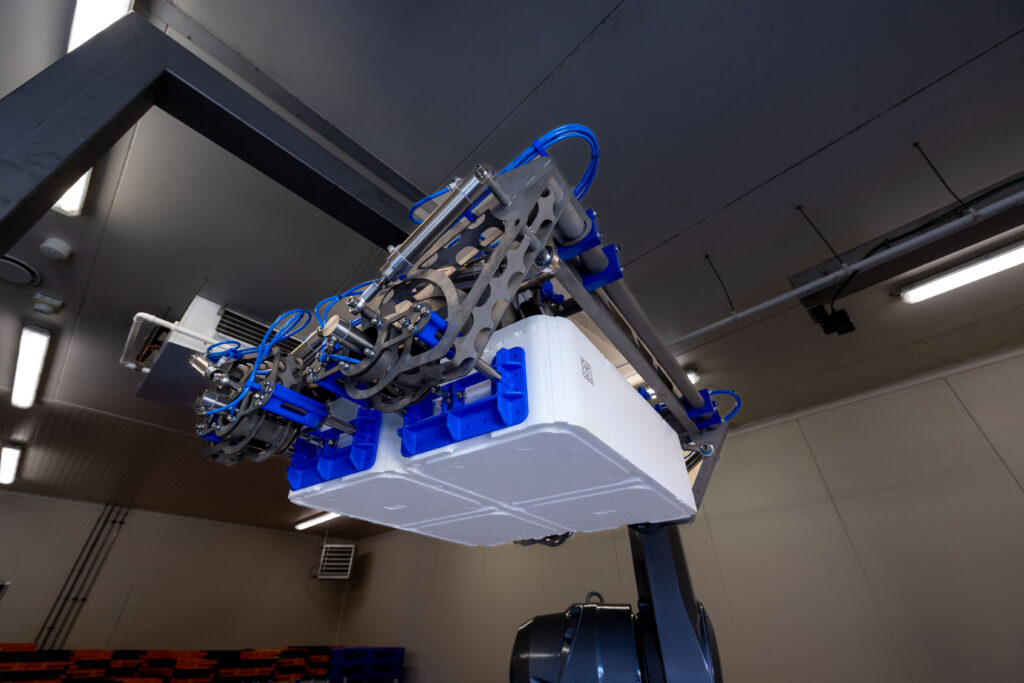

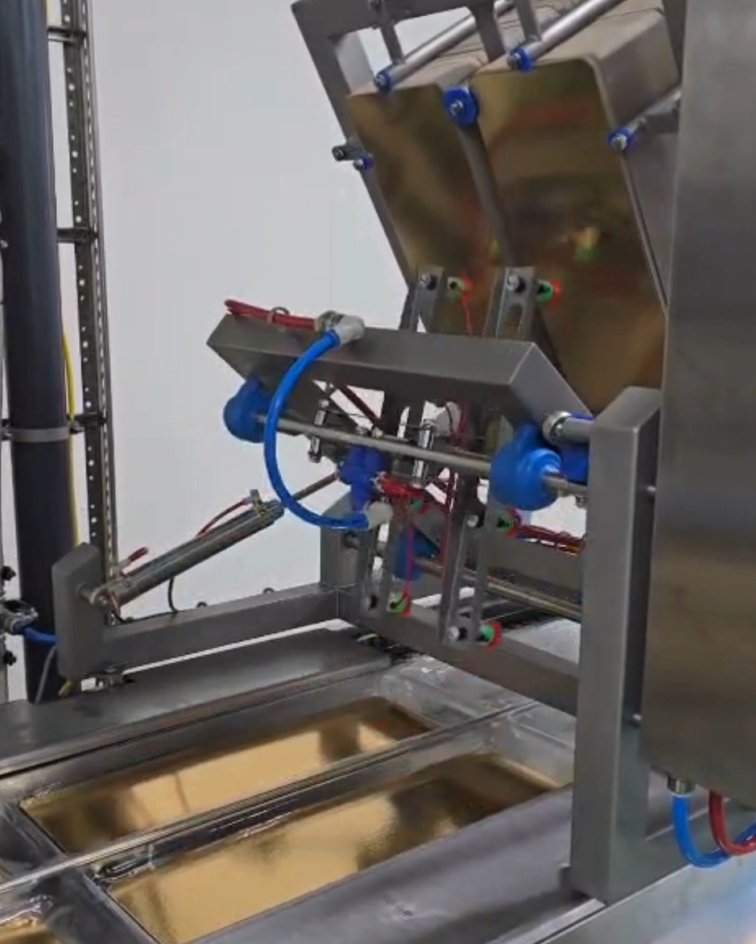

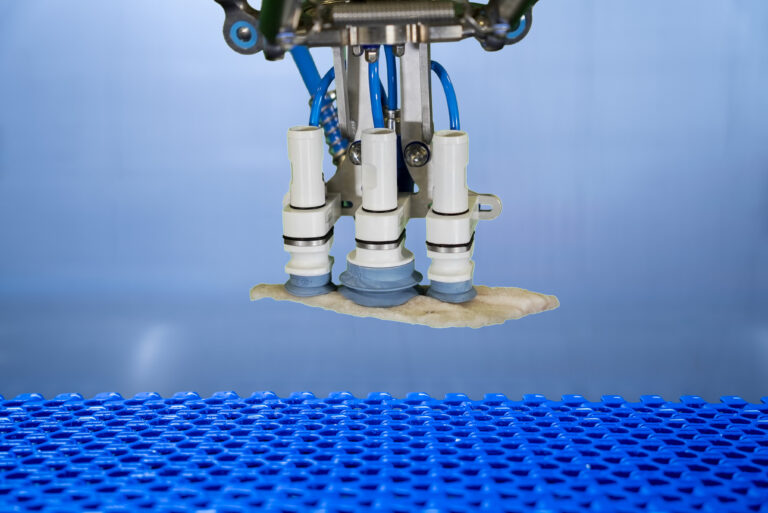

The robot cuts the straps, picks up the boxes, empties their contents, and stacks the empty boxes again, all while the straps are simultaneously shredded.

This six-axis robot is highly suitable for humid environments, such as food production facilities.

The operator places the pallet with boxes in a cage. The camera recognises the pattern of the boxes and sends a signal to the robot, which picks up two boxes at a time. The straps on the boxes on the deposit unit are automatically removed and, after being cut, automatically disappear into small pieces in a waste bag hanging under the unit. While the first two boxes are on the unit, the robot picks up the next two boxes (buffer). The lids are then automatically lifted and the boxes tipped over. Because the robot fixes the lid in place, the empty boxes, including the lids, are placed on the pallet after tipping. The only manual process is driving the pallets in and out. For the safety of the personnel, the robot and the units are located in a stainless steel cage with fencing. Automatic sliding doors give the operator access to the cage to move the pallets in and out. This ultimately saves two to three staff members on the line, as you only need one operator and no more production workers.

The Depalletiser is currently up and running at the production of Norwegian Seafood in Urk.

Link for the video here.