New Project launched at Visscher Seafood! 🚀

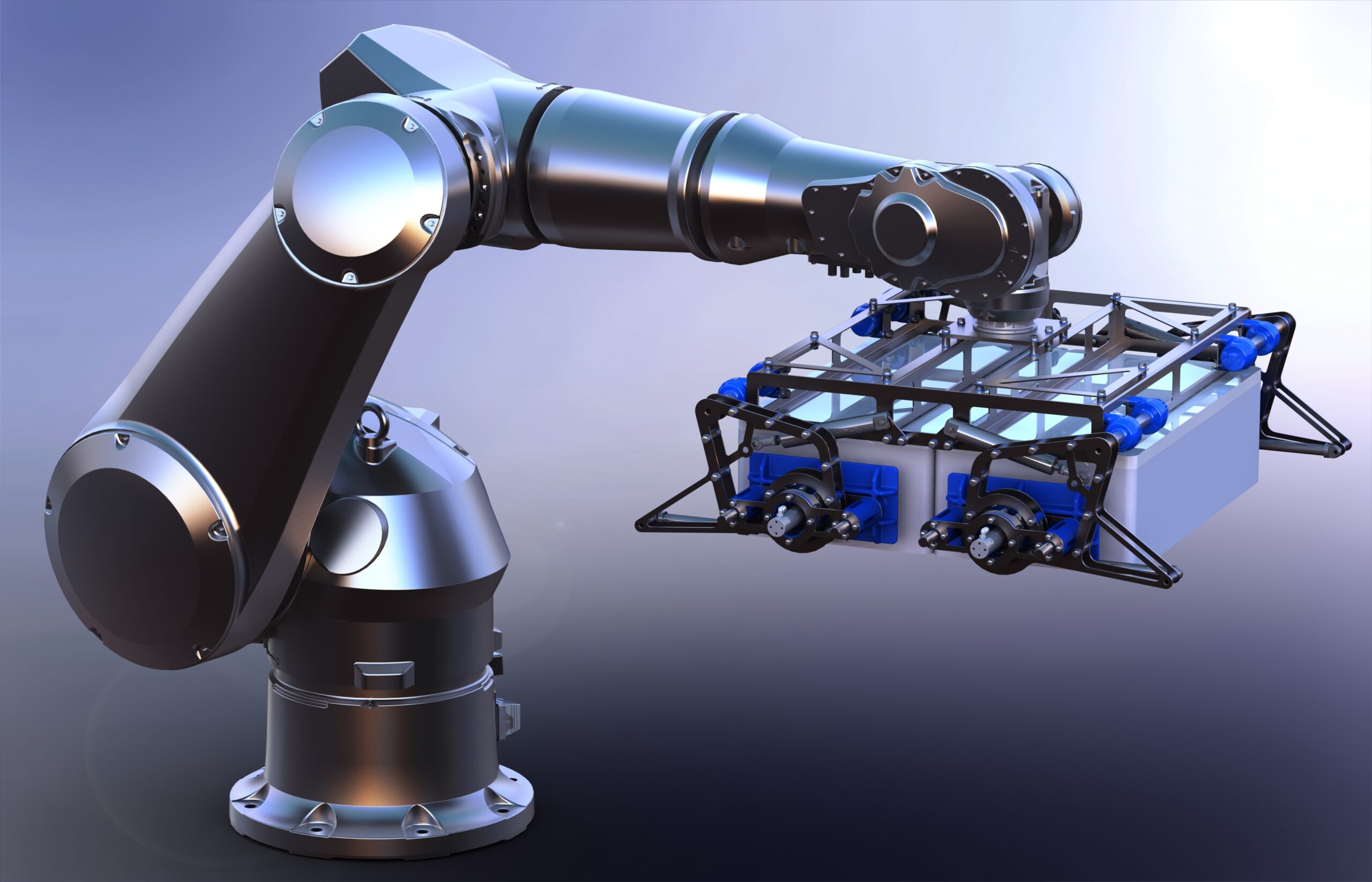

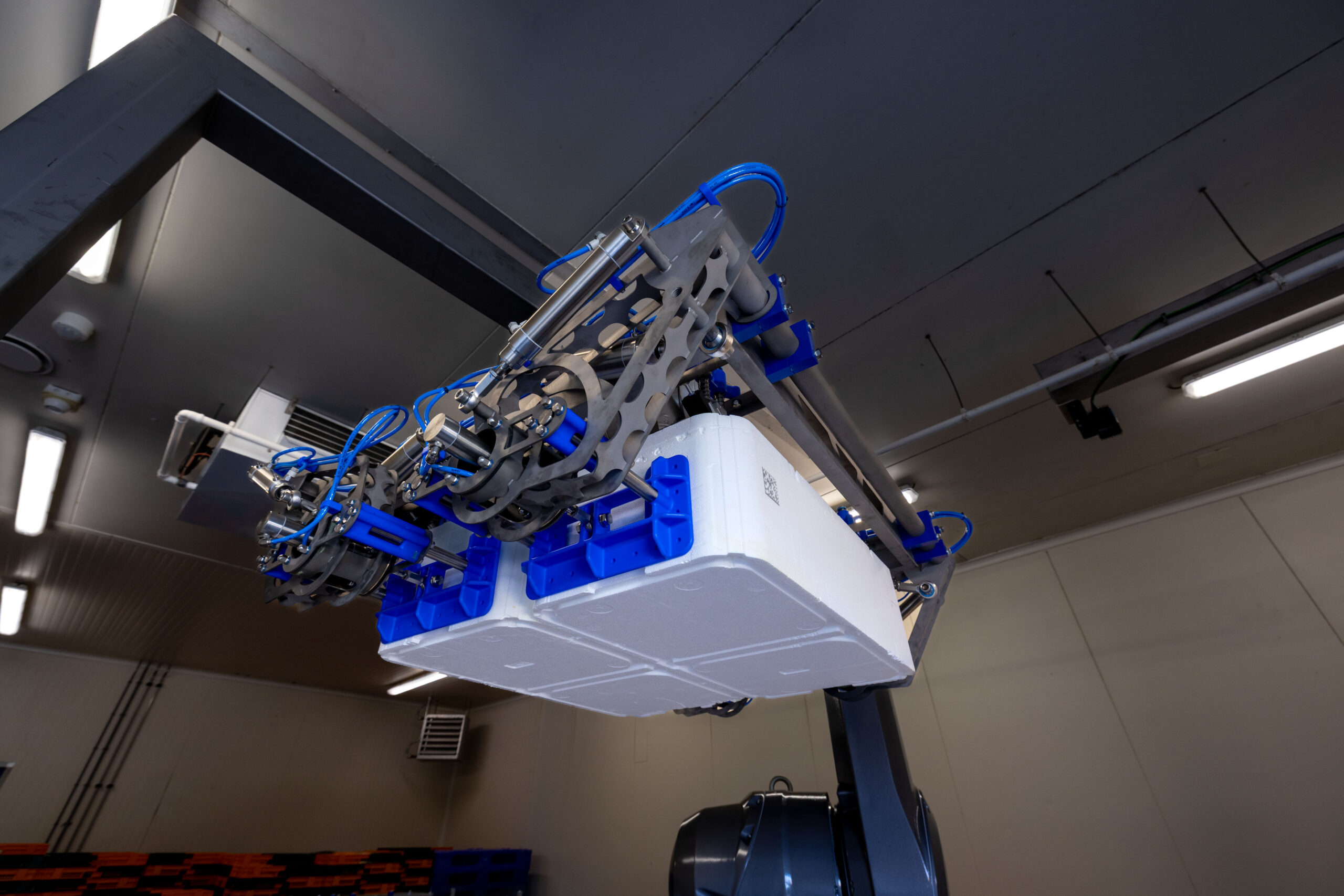

We completed this innovative project together with Visscher Seafood / Norwegian Seafood! In this project, we were working on the engineering and implementation of an advanced hygienic Depalletizer.

With a capacity of 10 pallets of salmon per hour, the Fish Depalletizer makes an immediate difference at the start of the production process.

The 6-axis robot picks up two boxes at a time and places them on the de-strapunits. After cutting the straps, the boxes are picked up, the lids opened and the contents tipped out. The empty boxes, including the lids, are neatly placed back on the pallet.

Some highlights:

- Double efficiency: our Depalletizer can pick up two bulk packs at the same time.

- Automatic straps cutting: for even more convenience and safety, the robot will automatically cut and shred straps.

- Automatic stacking: the empty boxes and lids are stacked neatly.

- Capacity: The robot can handle the capacity of the line.

Interested? Get in touch now. 📞

Developed with support from the MIT R&D subsidy (Province of Flevoland).